Manufacturers and Distributors of Vermiculite,

Insulating Materials

and selected Refractory Materials

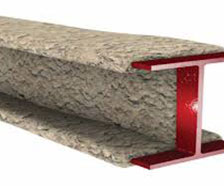

Insulating bricks and shapes are unique in that it is the only of its type done in South Africa with a ceramic bond

Some of the areas that the products find themselves in include applications such as refractory materials and waterproofing screeds

READ MORE

CONTACT US

Who Are We?

From the origins of manufacturing a limited range of vermiculite based insulating bricks the company has gradually expanded into other areas. So much so that they now supply several different grades of raw vermiculite and a wide range of exfoliated vermiculite grades. The exfoliated vermiculite can be used on a loose grain basis or can be further processed depending of the intended application. We for example process exfoliated vermiculite into high temperature insulation bricks.

However, what and who we are will always we defined by our passion to find solutions to problems related to vermiculite and its applications, as well by our drive to protect the environment, save energy and scares resources by applying our insulation material and design expertise.

What We Focus On!

In addition to our core products we also trade in related insulating materials such as mineral wool fibre based products and high temperature insulating firebrick (IFB). These include amongst others ceramic fibre based blankets, boards, textiles and vacuum formed products.

The high temperature insulating firebrick covers temperatures as low as 700 degree Celsius up to 1800 degree Celsius. The specific selection of IFB is done in cooperation with the customer by analysing their process and by matching our technical solutions to their specific heat containment situation. By sourcing a very specific product form a worldwide selection of possible products we are not limited by a fixed product range and thereby provide a unique engineered solution with every product supplied.

The above products find application in such diverse areas as the petrochemical, incineration, power generation, marine, space, fertilizer, automotive, jewellery, metallurgical and aeronautical industries.

INSUTECH (Pty) Ltd. For Your Insulation Solutions

Manufacturers and distributors of Vermiculite, Insulating Materials and Selected Refractory Materials

The insulating bricks and shapes Insutech manufactures are unique in that it is the only of its type done in South Africa with a ceramic bond. This ensures that customers get a product with no green shrinkage during use and thus no unexpected joints opening up.

Our vermiculite is also sourced from the world leader in raw vermiculite quality, namely a well-known South African mining giant. Most similar products to ours from across the world are based on vermiculite imported from this premium quality source.

Our in-house technical expertise in insulation technology allow us to not only sell these products, but to provide thermal profiles and predictions of temperatures that will be experienced at the cold end of high temperature production units.

We are a “preferred supplier” to a number of large companies in the metallurgical industries and supply many others industries that utilize heat and insulting material for heat retention either directly or through associate companies. We have long term supply contracts with some of these customers.

Technical support is a major service provided to either existing or potential customers. This takes the form of technical advice or assistance with projects both big and small.

Although most of their sales are restricted to Southern Africa they have both export and import licenses and have exported to amongst others Australia and Lesotho.

PRODUCT OVERVIEW

Manufacturers and distributors of Vermiculite, Insulating Materials and Selected Refractory Materials

Typical Applications for Insulation Material

- High temperature furnace and kiln linings

- High temperature gaskets and seals

- Heat shields

- Gas boiler combustion chamber linings

- Hot gas duct linings

- Domestic appliances and structures

- Molten metal transfer systems

- Refractory back-up insulation

- Ingot mould liners

- Automotive transfer systems

- Expansion joints

Typical Benefits of Insulation Material

Its light weight and low thermal conductivity (k-value) allows for thinner furnace walls, improved energy conservation and lower operating costs

With a specific heat of 0,8 kJ/kgK lower heat storage versus denser brick means reduced fuel costs in particularly cyclically operating heating/firing equipment

By absorbing excess expansion and thermo-mechanical stress it prevent shell deformation.

By keeping the exposed surface of a refrigerated system above dew point it prevents condensation and the resulting corrosion.

APPLICATIONS

© 2016 Insutech (Pty) Ltd. | Sitemap

4 Turk Street

Olifantsfontein, 1666

Gauteng

South Africa

Website developed by: